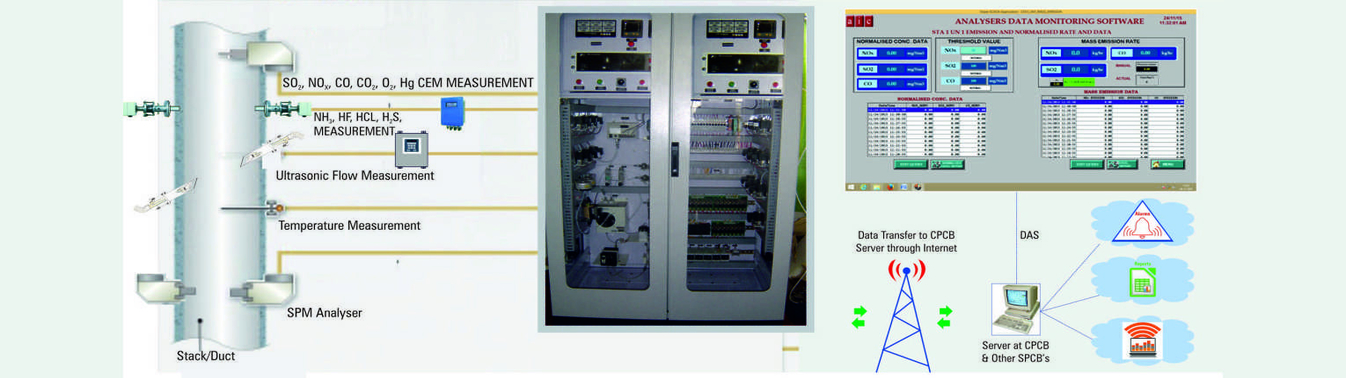

Continuous emission monitoring involves measuring gas concentration at the point of emission(stack/Duct).

These measurement can be coupled with temperature, pressure and flow measurements to allow a better understanding of how emission affect the local and broader environmental. Stack emissions monitoring involves monitoring high concentration of stack air such as CO, CO2, Nox SO2 and others with specially designed gas analysers.

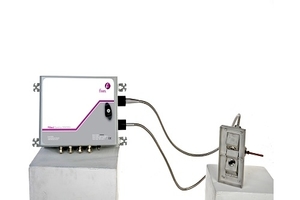

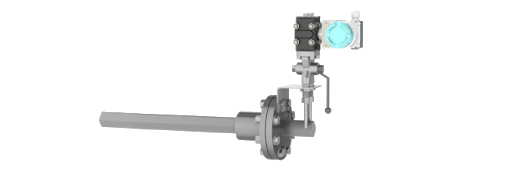

Our analyser system package includes Heating , Ventilation and air conditioning systems, Pre conditioning units for samples, Including pressure and temperature control. Sample probes and data management software and hardware, and other supporting systems as required.

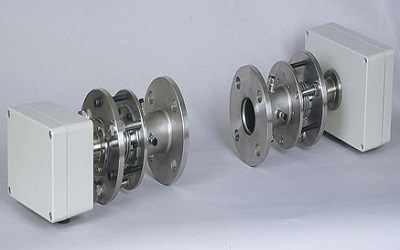

AIC Provide Optimum solution to the measurement and monitoring of various pollutants like SO2, NOX, CO, CO2, NH3, HCL, HF, THC, Mercury, etc Based on the vast experience in such systems, AIC today provide solutions on technology platforms of either Dilution Extractive, Hot Extractive or in-situ measurement.

AIC Provides complete CEMS Package suitable for use in industries which fulfill the specific requirements of state and central pollution control boards.